Have you ever wondered how the products you buy make their way from factories to your doorstep? Or how companies manage to keep shelves stocked with your favorite items, even during peak shopping seasons? The answer lies in a fascinating process called supply chain management (SCM). Whether you’re a business owner, a curious consumer, or someone looking to understand the backbone of modern commerce, this article will break down everything you need to know about supply chain management in simple, relatable terms.

Supply Chain Management in Simple Words

Let’s start with the basics. Imagine you’re baking a cake. You need ingredients like flour, sugar, eggs, and butter. Now, think about where those ingredients come from. The flour might come from a mill, the sugar from a sugarcane farm, and the eggs from a local farmer. Once you have all the ingredients, you mix them, bake the cake, and serve it.

Supply chain management is like the process of baking that cake, but on a much larger scale. It’s the art and science of getting raw materials, turning them into products, and delivering those products to customers—efficiently and cost-effectively. It’s the behind-the-scenes magic that ensures everything runs smoothly, from the factory floor to your shopping cart.

Supply Chain Management: Definition

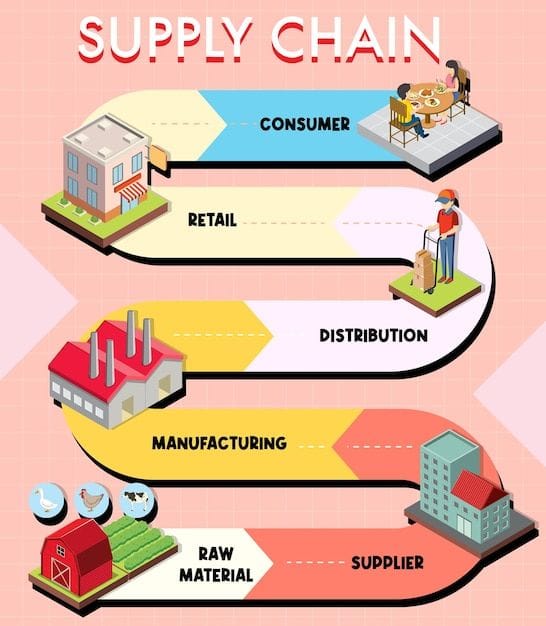

So, what exactly is supply chain management? In technical terms, supply chain management is the oversight of materials, information, and finances as they move from supplier to manufacturer to wholesaler to retailer to consumer. It involves coordinating and integrating these flows both within and among companies.

But let’s break it down further. Think of SCM as a giant relay race. Each participant—suppliers, manufacturers, distributors, and retailers—passes the baton (in this case, the product) to the next until it reaches the finish line (the customer). The goal? To make sure the baton is passed quickly, smoothly, and without any hiccups.

Importance of Supply chain management

Supply chain management might not sound like the most exciting topic at first glance. But here’s the thing: it’s the unsung hero that keeps the world moving. From the food on your table to the phone in your hand, supply chain management plays a crucial role in making sure products are available when and where you need them. So, why does it matter so much? Let’s dive in.

Keeping Customers Happy

Imagine walking into your favorite store only to find empty shelves. Frustrating, right? That’s where supply chain management comes in. By ensuring products are stocked and delivered on time, SCM keeps customers satisfied and loyal. Whether it’s a last-minute gift or your weekly groceries, a well-managed supply chain makes sure you get what you need, when you need it.

Saving Money and Reducing Waste

Efficiency is the name of the game in supply chain management. By streamlining processes, businesses can cut costs and reduce waste. For example, better inventory management means fewer overstocked items gathering dust in warehouses. Optimized transportation routes save fuel and reduce delivery times. These savings don’t just benefit companies—they often translate into lower prices for consumers.

Staying Ahead of the Competition

In today’s fast-paced world, businesses need to be quick on their feet. A strong supply chain gives companies a competitive edge by allowing them to respond swiftly to market changes. Whether it’s a sudden surge in demand or a new trend, businesses with efficient supply chains can adapt faster and outperform their rivals.

Managing Risks and Disruptions

Life is full of surprises, and supply chains are no exception. Natural disasters, pandemics, or even a supplier going out of business can disrupt operations. A robust supply chain is designed to handle these challenges, ensuring businesses can keep running smoothly even when the unexpected happens.

Supporting Sustainability

With growing concerns about climate change, supply chain management is also playing a key role in promoting sustainability. From reducing carbon footprints to using eco-friendly materials, SCM helps businesses operate in a way that’s better for the planet.

In short, supply chain management is the backbone of modern commerce. It’s what keeps businesses running, customers happy, and the world moving forward. Without it, the products we rely on every day simply wouldn’t be there. So, the next time you enjoy a meal, put on a new outfit, or unbox an online order, take a moment to appreciate the incredible system that made it all possible

History of Supply Chain Management

Supply chain management isn’t a new concept. In fact, it has been around for centuries, evolving alongside trade and commerce. Let’s take a quick trip down memory lane:

- Ancient Times: Even in ancient civilizations, people traded goods like spices, silk, and gold. While the processes were rudimentary, the basic idea of moving goods from one place to another was there.

- Industrial Revolution: The 18th and 19th centuries brought mass production and railroads, making it easier to transport goods over long distances.

- 20th Century: The rise of globalization and technology transformed supply chains. Concepts like just-in-time manufacturing and computerized inventory systems emerged.

- 21st Century: Today, supply chains are more complex than ever, thanks to e-commerce, artificial intelligence, and the Internet of Things (IoT).

From camel caravans to self-driving delivery trucks, supply chain management has come a long way!

The 5 Key Components of Supply Chain Management

Supply chain management is like a well-choreographed dance, with each step carefully planned to ensure everything runs smoothly. To understand how it all comes together, let’s break it down into its five key components. Each plays a critical role in ensuring products move seamlessly from raw materials to your hands.

1. Planning

Planning is the foundation of any successful supply chain. It’s where businesses forecast demand, set production goals, and create strategies to meet customer needs. Think of it as the blueprint for the entire operation. Without proper planning, companies risk overstocking, understocking, or missing deadlines. Tools like data analytics and market research help businesses predict trends and stay ahead of the curve.

Read more about Supply Chain planning

2. Sourcing

Once the plan is in place, the next step is sourcing. This involves finding reliable suppliers who can provide the raw materials or products needed. It’s not just about getting the best price—it’s also about quality, reliability, and ethical practices. Strong relationships with suppliers are crucial, as delays or poor-quality materials can disrupt the entire chain.

3. Manufacturing

This is where the magic happens. Raw materials are transformed into finished products through production processes. Efficiency is key here, as manufacturers aim to produce high-quality goods while minimizing waste and costs. Technologies like automation and robotics have revolutionized this stage, making production faster and more precise.

4. Delivery

Once products are ready, they need to reach their destination. Delivery involves logistics—transporting goods to warehouses, retailers, or directly to customers. This stage requires careful coordination to ensure timely and cost-effective shipping. With the rise of e-commerce, last-mile delivery (the final step to the customer’s doorstep) has become a major focus for businesses.

5. Returns

Not every product stays with the customer. Sometimes, items are defective, damaged, or simply unwanted. The returns process, also known as reverse logistics, ensures these products are handled efficiently. This includes refunds, repairs, recycling, or restocking. A smooth returns process is essential for maintaining customer trust and satisfaction.

Together, these five components form the backbone of supply chain management. When each one works in harmony, businesses can deliver value to customers while staying competitive and efficient.

Different Supply Chain Models

Not all supply chains are created equal. Depending on the industry, product, or business goals, companies use different models to manage their supply chains. Here’s a quick overview of the most popular ones:

1. Agile Supply Chain Management

Agile supply chains are all about flexibility. They’re designed to respond quickly to changes in demand or market conditions. For example, during a sudden spike in demand for umbrellas during a rainy season, an agile supply chain can ramp up production and delivery without breaking a sweat.

2. Lean Supply Chain Management

Lean supply chains focus on eliminating waste—whether it’s excess inventory, unnecessary steps, or inefficient processes. The goal is to do more with less, maximizing value for the customer while minimizing costs.

3. Six Sigma

Six Sigma is a data-driven approach that aims to improve quality by identifying and eliminating defects. In supply chain management, it’s used to streamline processes and reduce errors.

4. Total Quality Management (TQM)

TQM is a holistic approach that involves everyone in the organization, from top management to frontline workers, in improving processes, products, and services. It’s about creating a culture of continuous improvement.

5. Resilient Supply Chain Management

Resilient supply chains are built to withstand disruptions. Whether it’s a natural disaster, a pandemic, or a supplier going out of business, a resilient supply chain can adapt and keep operations running smoothly.

6. Green Supply Chain Management

With growing concerns about climate change, many companies are adopting green supply chain practices. This involves reducing environmental impact by using sustainable materials, minimizing waste, and optimizing transportation routes.

7. Digital Supply Chain Management

The digital supply chain leverages technology like IoT, AI, and blockchain to enhance visibility, efficiency, and decision-making. Imagine a supply chain where every product, pallet, and truck is tracked in real-time—that’s the power of digital SCM.

The Future of Supply Chain Management

As technology continues to evolve, so does supply chain management. Here are some trends to watch out for:

- Artificial Intelligence (AI): AI is revolutionizing SCM by predicting demand, optimizing routes, and automating repetitive tasks.

- Blockchain: This technology ensures transparency and security in supply chains, making it easier to track products and prevent fraud.

- Sustainability: Consumers are increasingly demanding eco-friendly products, pushing companies to adopt greener supply chain practices.

- Autonomous Vehicles: Self-driving trucks and drones could soon become a common sight in supply chains, reducing costs and improving efficiency.

The future of supply chain management is exciting, to say the least. As businesses continue to innovate, the possibilities are endless.

Summary

Supply chain management is more than just a business concept—it’s a vital part of our everyday lives. By understanding how it works, we can better appreciate the complexity and beauty of the world around us. Whether you’re diving into the world of SCM for the first time or looking to deepen your knowledge, remember this: the supply chain is the heartbeat of commerce, and it’s here to stay.